CHAPTER II

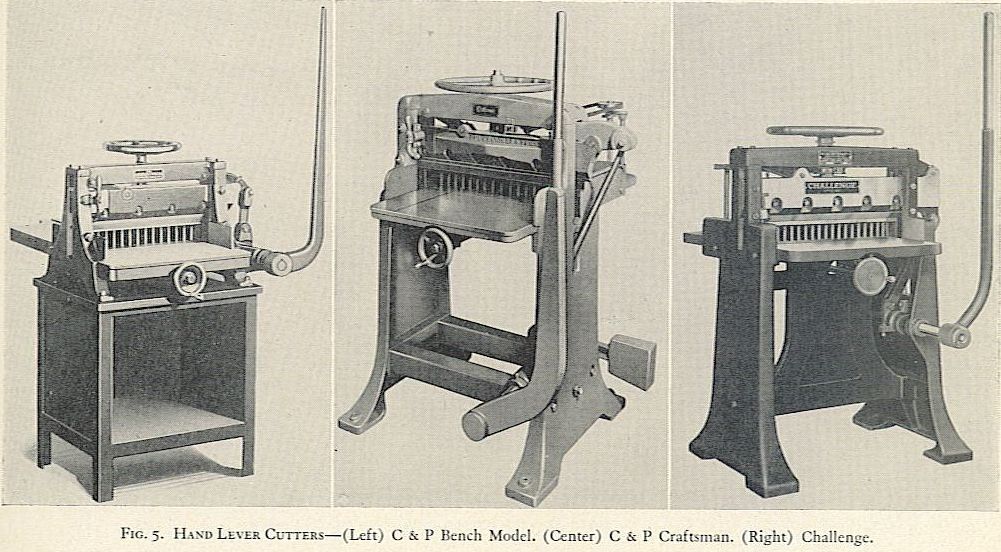

Hand Lever Cutters

LEVER cutters are made for use in schools, offices and small printing plants. Sizes now made are 26 and 30 inch floor models and 16, 18 and 19 inch table models.

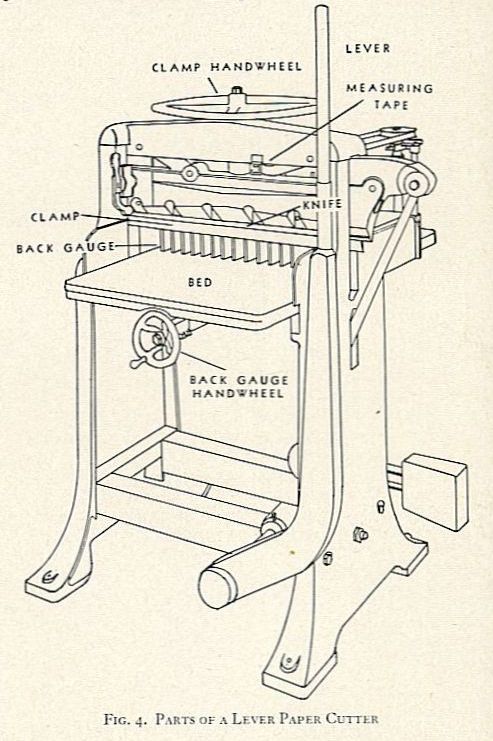

To set the back gauge to a given measure. Unlock the set screw holding the handwheel underneath the front of the cutter bed. Turn the handwheel until the back gauge is moved back beyond the desired measure. Reverse the handwheel and move the back gauge forward to the measure. Lock the set screw.

Example: The back gauge is set at 4 inches: the cut wanted is 9 inches. Move the back gauge to to inches and forward to 9 inches. Always move the back gauge forward to a setting to compensate for wear or play in the gear or chain connecting the gauge with the handwheel.

To place paper in the cutter. Insert the jogged edges (the guide and gripper edges of printed sheets) toward the back and one side. Handle the stcck in small lifts for accuracy. Bend the sheets so the top sheets of the pile angle out toward the operator. This will help counteract the friction which retards the bottom sheets as the stack is pushed toward the back gauge.

To clamp and cut. After the stock is accurately placed insert a strip of heavy cardboard under the clamp to protect the stock pile from clamp marks. In some cases it is better to attach a strip of binder’s board underneath the clamp with padding compound to protect the stock pile.

Apply clamp pressure by turning the large wheel above the cutter frame. Bring the knife down until it touches the paper. then pull the knife through the stock with, a long continuo:Is motion until the last sheet has been cut. Do not attempt to push the knife through a stock pile.

Do not hack or chop the paper with short motions of the knife. These hacking motions produce undue strain upon the muscles of the operator’s shoulders. In addition, there is possibility that the knife may be chipped or feathered. Hacking and chopping produces inaccurately cut paper and will dull the best knife in a few hours.

To change a cutter knife. Lower the knife until it touches the cutting stick. Remove knife bolts with a socket wrench. Lift the lever until the knife holding bar is clear of the knife. Insert two bolts (or preferably, handles, if available) into the knife holes to use as handles in removing. Lift the dull knife from the cutter and place flat in a safe location. Clean dirt, grease or paper chips from the knife slot and knife holding bar. Change the cutting stick.

Remove the sharpened knife from its shipping cover. Clean the protecting oil from both surfaces of the knife. Insert bolts (or handles) to use in lifting. Carefully place the sharp knife into position with the sharp edge resting upon a small pile of scrap paper. Lower the knife holding bar to contact and cover the knife. Align bolt holes and insert all bolts. Tighten the bolts with a socket wrench. Tighten the square-head adjusting screws at each end of the knife holding bar (upper side) to remove cutting pressure from the bolts. Return the knife to its upper position.

Rub the dull knife with an oiled cloth to protect it from rusting and insert it into a shipping cover for sharpening.

Maintenance. All cutter bearings should be oiled once monthly with a heavy weight (SAE 50) machine oil. The spiral gear of the clamp should be greased or treated with graphite, since oil would drain on to the paper.

Occasionally the operator will find a cutting stick which is not true. In such cases the stick may be built up to parallel the knife by placing strips of thin paper in the groove in the cutter table underneath the low section. Do not place chipboard over the cutter stick. Chipboard contains foreign matter which tends to dull or nick the knife.

For best results the cutter bed should be kept clean and highly polished with paste wax to reduce friction. Avoid jogging paper against the back gauge.

Manufacturers of lever paper cutters:

CHALLENGE, 26 1/2, and 30 1/2, inch, hand clamp. Maximum height of pile 3%..i inches. May be equipped with a knife bar lock and safety device requiring both hands on the lever before the knife can be lowered. Made by the Challenge Machinery Company, Grand Haven, Michigan.

CHALLENGE PONY, 19 inch, hand clamp. Maximum height of pile 2 1/2, inches. Made by Challenge Machinery Company.

CHANDLER AND PRICE BENCH MODEL, 19 inch, hand

clamp. Maximum height of pile 2 3/4 inches. Made by the Chandler and Price Company, 6000 Carnegie Avenue, Cleveland, Ohio.

CRAFTSMAN, 26 1/2, inch, hand clamp. Maximum height of pile 3 3/4 inches. Equipped with two-hand safety control. Made by the Chandler and Price Company.

LEVER UNDERCUT, 30 inch, automatic clamp. Maximum height of pile 2 1/2, inches. Straight or shear cut. Made by Smith and Winchester Manufacturing Company, South Windham, Connecticut.

PEERLESS GEM, 25 and 30 inch, hand clamp. Made by the Missouri-Central Type Foundry, 701 East Murdock Avenue, Wichita, Kansas.

UTILITY PONY, 16 and 18 inch, table model, hand clamp. Made by the Pavyer Printing Machine Works, 600 South Broadway, St. Louis, Missouri.