CHAPTER V

Techniques in Handling Paper

AS THE MAJOR RAW MATERIAL used by the printer, paper presents several problems upon whose solutions depend the quality and speed of the printing and usually the profits derived. These problems arise from the fact that paper is quite heavy for its volume, yet is so fragile as to require constant vigilance in handling. Its surfaces must be protected from soil, its color from exposure to strong light, and its fibre content from humidity changes. Before printing, the trimmed edges. the felt and wire sides and the watermarks must be kept in order; after printing, the guide edges must be watched.

Storage. The ideal paper storage room should have a temperature and humidity equal to that of the pressroom and bindery where the paper will be used. The windows should be located or shielded so the paper is at no time exposed to the direct rays of the sun. Many papers, particularly gummed stocks, need protection from rodents and insects.

Upper left (a) Roll the edges. Upper right (b) Air the sheets by pulling top sheets taut. Lower left (c) Stand the sheets on edge and jog. Lower

right (d) Remove excess air.

After the manufacturing process is completed, paper is inspected and the imperfect sheets are discarded. The sheets are counted and packed for shipment. Waterproof wrappers, cartons, wooden cases and skids are used to protect the edges and surfaces from damage and soil, and the fibre content from moisture changes. Incoming papers should be left in mill or warehouse wrappings until press time. Where possible papers should be purchased in advance of use and stored for seasoning to allow the fibre content to absorb or release moisture and heat.

Acute changes in the moisture content of paper cause curling of the sheets and wavy ekes. Sheets which are too dry give trouble from static electricity. Sheets too wet are not receptive to oil base inks. All possibilities of the paper coming into contact with water must be eliminated, for example, leaking roof or leakage in steam and water lines. For the same reason paper should never be stored in direct contact with a wall or floor.

Plants located in extremely wet or dry climates may order paper with a predetermined high or low moisture content. It is doubly important that these papers be held in their original wrappings until used.

Large sheets in quantity are shipped on skids, banded with steel straps. Skids may be moved easily by use of low- wheeled lifts which roll under the skid and lift it slightly. When using skid storage adequate aisle space to turn the skid is essential. Labels and ream markers should be next to the aisle for ease in identifying the stock. Where power lifts are used the skids may be stored one on top of the other, providing a check is made to assure that the floor will withstand the large concentration of weight in one area.

Sheets 25 x 35 inches and smaller generally are shipped in cases, cartons or packages and where possible should be left in those wrappings for maximum protection. Shelving of appropriate size may be built for the various standard sizes of papers. In placing the papers, labels and ream markers should be on the outer exposed side. Storing of similar kinds of papers together will assist the stock man in locating the stock easily and in maintaining an orderly procedure.

Every stock room should have a perpetual inventory. Not only will such an inventory prevent unnecessary running out of papers, hut will enable the printer to determine approximate amounts of paper used from year to year. These amounts may be used for making quantity purchases with the resulting savings in paper cost.

Protection of paper in use. Quite obviously, careful handling by the workmen is the most effective means of protecting the paper during its travel through the printing and binding operations. The workmen should be assisted by those labor-saving devices applicable to the size of the plant. Large sheets in quantity may be shifted on skids with lift trucks. Smaller sheets should be transported on wheeled tables equipped with built-up sides to protect the edges of the paper. Carrying large quantities of paper by hand should be avoided. When moving paper on skids or tables the operator must be careful not to bump or jar the stack suddenly. Sudden starting or stopping will cause the top sheets to slide off the pile. Top sheets must be protected when the paper is near air currents, such as fans, open .vinclows or elevator shafts.

A second help is to maintain a clean plant with all equipment in good repair. Paper in use is subject to the same possibilities of damage as paper in storage, but to a greater degree since the protective wrappers have been removed. Contact with dirt, oil, water, adhesives, cleaning fluids or ink will soil the surface of the sheets. As in storage sheets should not be exposed to sunlight for an’ long period. Avoid leaving sheets near heating units or sinks to prevent changes in moisture content.

Observe safety rules. Every workman handling paper should be reminded periodically of two dangers: flesh cuts from edges of sheets and rupture from lifting heavy loads of paper incorrectly.

An exposed edge of a single sheet can be razor sharp. capable of inflicting a deep cut. When this happens the wound should be washed immediately with clear cold water and treated with antiseptic to prevent infection. To avoid being cut by paper edges the workman should keep his hands soft and pliable with frequent applications of pure glycerine rubbed into the pores of the hands andwrists. Soft flesh will give under the pressure of a sharp paper edge in the same manner that a sponge gives under a sharp knife.

Paper is heavy. Careless lifting of large quantities provides an ever present possibility of rupture. Lifting should be done from the hips and knees with shoulders erect. In addition to being dangerous, attemps to lift overloads tire the operator quickly and cause unnecessary increases in jogging time.

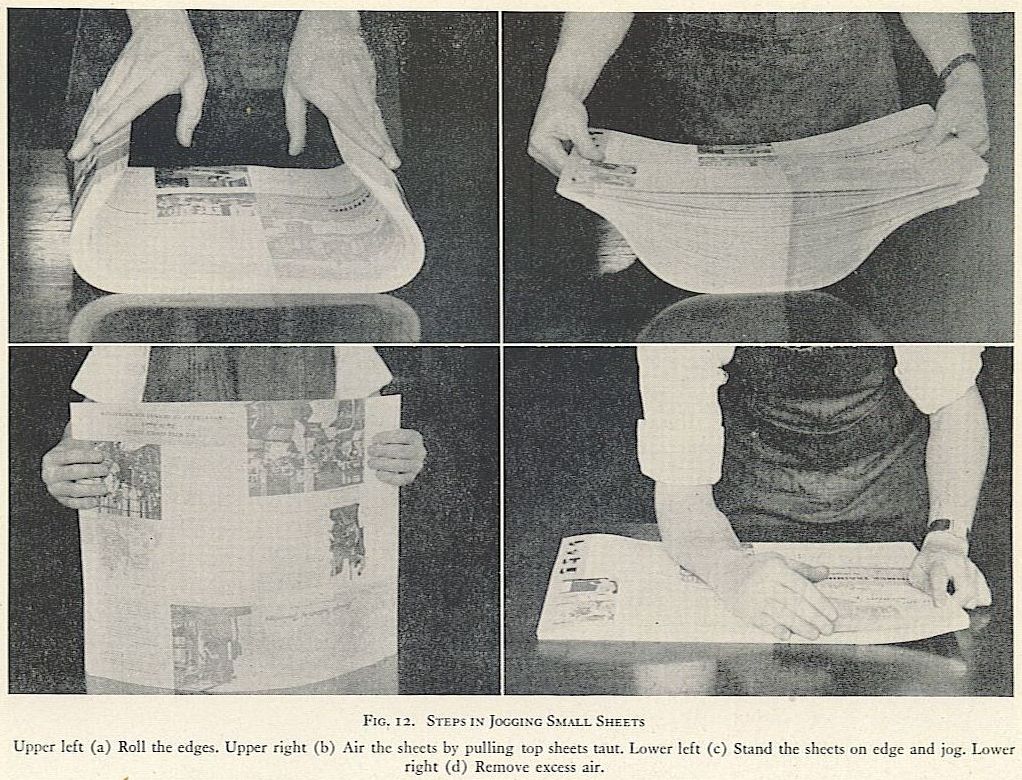

To jog small sheets into an orderly stack. Efficient jogging requires a cushion of air to be placed between the sheets in the stack to overcome friction of the sheets sliding against each other or the effects of static electricity. Speed in jogging depends upon selecting the correct maximum amount of paper to the jogged at one time.

Determine the number of sheets which may be handled with ease. Place hands under opposite edges as pictured. Lift the edges and roll slightly until the lift resembles a lj shape. Grasp the lifted edges firmly with each hand and pull the top sheets taut. Stand the sheets on edge and allow them to drop to the jogging table. Repeat the process until all sheets are even on the jogged edge, then turn the stack at right angles and repeat the process with one end of the stack until two edges are even. Remove the air from the sheets by holding the pile with one arm and ironing the air out with the other arm moving from side to side. Dexterity in jogging requires much practice.

Caution must be observed to prevent damaging edges of the sheets. Always jog printed sheets to guide edges. Avoid turning sheets end-for-end or upside down.

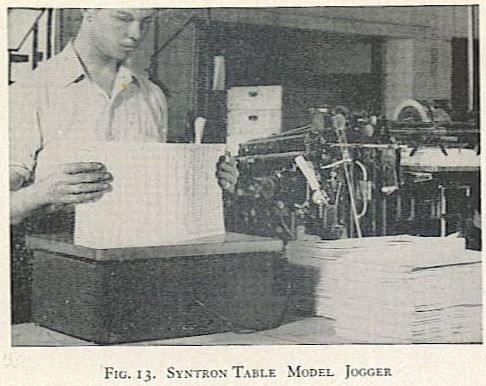

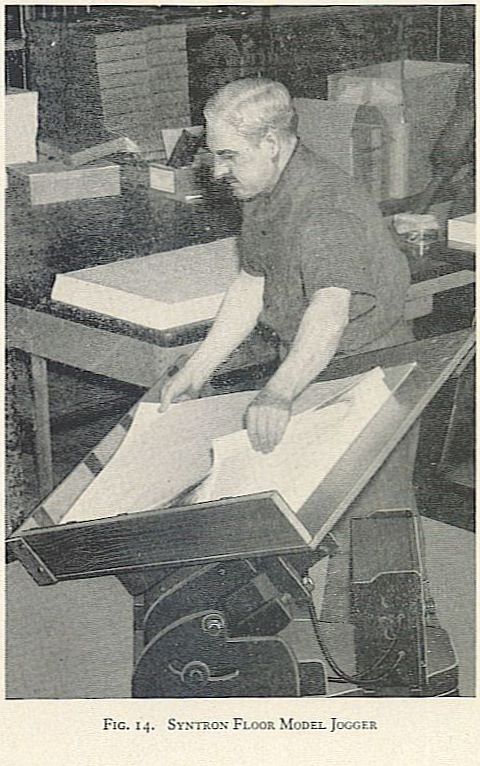

Many firms speed their jogging operation by installation of vibrating tables. (Figures 13 and 14.) These machines have a surface vibrating at high frequency which contacts the edges of aired lifts and jars the sheets into an even pile.

Four methods of count:ing paper. Large, flexible sheets of light and medium weight papers, such as book or bond, may be counted by separating the sheets as shown in figure 15a. Hold the stock with the left hand. With the right hand grasp a pile of stock about an inch thick and bend toward the left hand as illustrated. Pull the upper sheets toward the body until the pile is well separated. Release the left hand to count the separated sheets in threes, fours or fives. Counted sheets may be rolled back in fifties or one hundreds to assist the operator in remembering his count.

Papers too small or too stiff to be handled easily by the first method may be counted by fanning and counting inthrees, fours or fives. Again, groups of 50 or too should be set aside to assist in remembering the total.

Where extreme accuracy in counting is unnecessary, a rough count may be made by counting one group of a convenient number and dividing the remaining sheets into piles of equal height by matching with the counted pile, then computing the total in one pile dines the number of piles.

A rough total may be figured by counting one group of a convenient number, measuring the height of the resulting stack, and dividing that into the height of the entire pile. For example, if 500 sheets make a pile 2 inches high, then a pile 20 inches high would contain 5,000 sheets. When using this method hand pressure should be applied to both stacks during measurement to squeeze out some of the air cushioning the sheets apart.

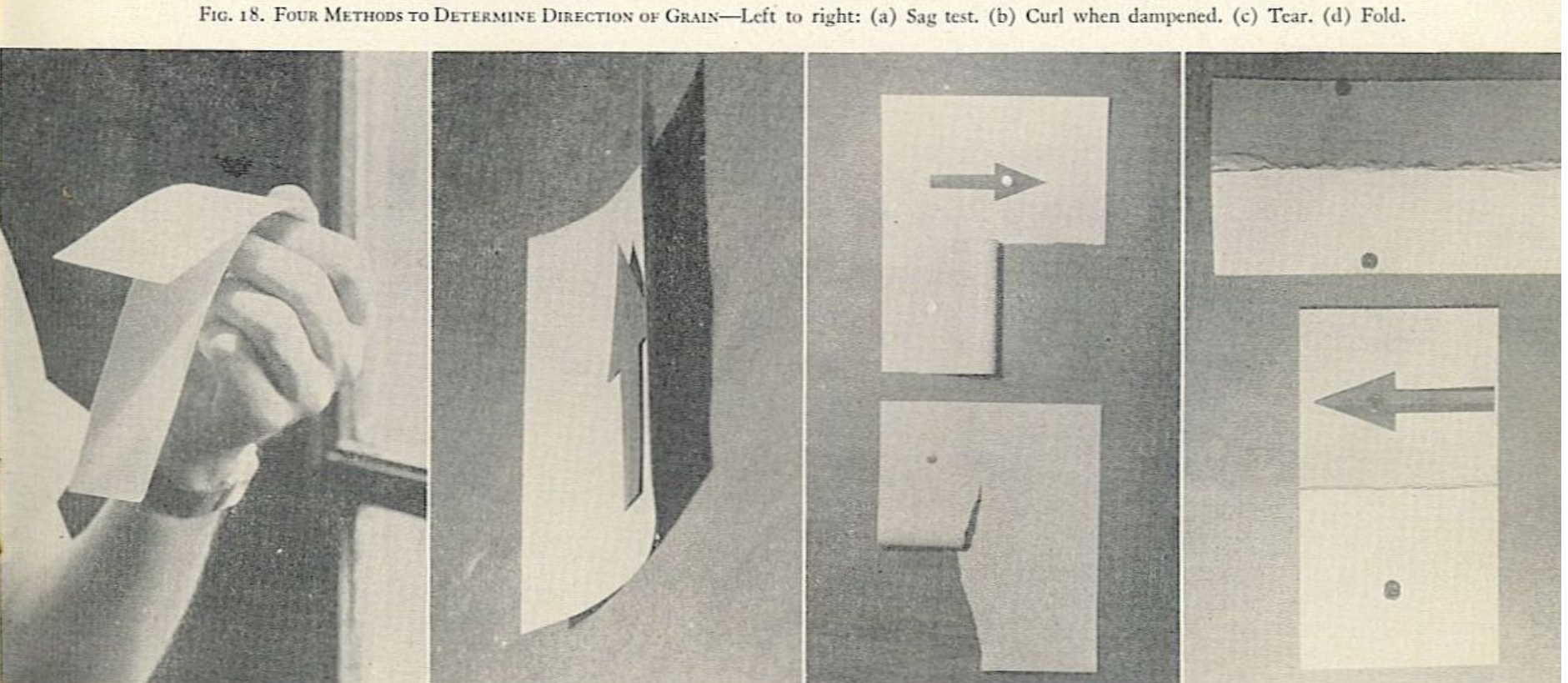

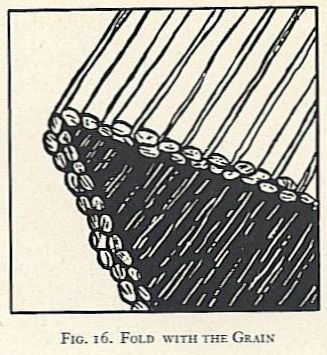

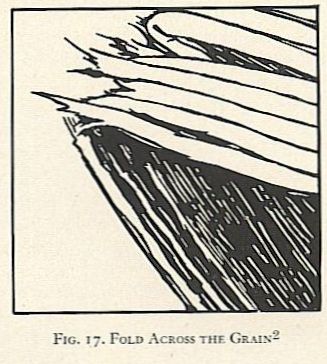

Four ways to determine direction of grain. Direction of the grain in medium and heavy weight papers may be found easily by tearing or folding the sheet parallel to two edges at right angles to each other. When torn in the direction of the grain, the sheet should break in an even straight line.

When torn across the grain the break will be ragged. (Figures 16 and 18.) A fold made in the direction of the grain will have a uniform edge, whereas a fold across the grain will he ragged and uneven. (Figures 17 and 18d.) These tests work best on heavy weight book and bond papers, ledger, cover papers and cardboards.

A third test determines grain by comparing the amount two strips of a sheet will sag under their own weight. Tear two strips of equal length and width (approximately inch by 5 inches) from the sheet to be tested. The first strip should be torn parallel to the length of the sheet, the second parallel to the width. Hold the strips at one end as illustrated in figure 18a. The strip sagging the lower of the two has its grain running across. The less flexible strip has its grain running lengthwise.

Sized or coated papers may be tested by wetting a small square with a cloth or sponge. The paper will curl with the grain running lengthwise.