GODEY’S LADY”S BOOK

PHILADELPHIA, NOVEMBER, 1852.

ILLUSTRATED WITH PEN AND GRAVER.

BY C. T. HINKLEY

A DAY AT THE BOOKBINDERY OF

LIPPINCOTT, GRAMBO, & Co.

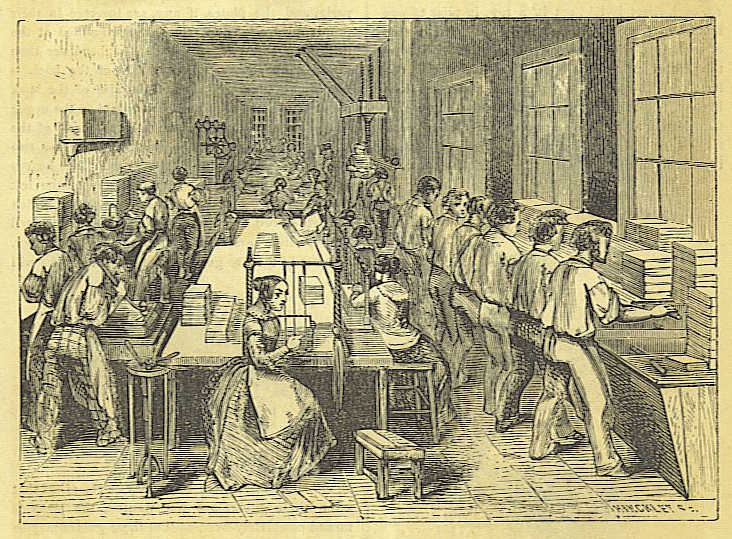

Having given our readers, in our last article, an insight into the mechanical operation required to set the types and print the sheets of a book, we this month take them to one of the largest publishing houses in the country, that they may know something of the manner in which books are bound and circulated through the Union. We are enabled to do this through the courtesy of Messrs. Lippincott, Grambo, & Co., who allowed us the privilege of examining their extensive range of rooms, a general idea of the labor performed in which we shall endeavor to give in the following pages.

When we received the consent of the senior partner of the firm for this privilege, we expected to see much that would surprise us, but were not prepared to find so vast an amount of business performed, or capital invested. We were completely lost in astonishment, as we passed through room after room peopled with workmen engaged in the various branches to which the rooms were devoted.

It was our intention, at first, to give a description of bookbinding only, but were so struck with the extent of labor employed in the establishment, that we have concluded, so far as we are able, to make our readers acquainted with the general machinery of a large publishing house, hoping it may prove as interesting to them as it was to us. We will first describe the

BOOKBINDING DEPARTMENT.

After the sheets are finished in the drying-room, as described in our last, and are pressed, they are sent in bundles to the bindery, where they are opened and given out to the girls employed to fold them.

When the whole of the impression has been folded, each sheet is laid out in a row, in piles of one hundred. The folder then takes one from the top of each pile, and, placing them together, they form the printed matter of a book. The copies thus collected are knocked evenly together, and put into a hydraulic press, between steel boards, in rows of two deep, and as many along-side of each other as the boards will hold, for the purpose of compressing them into a compact form.

If the work be newly printed, care must be taken not to allow it to set off as the fresh ink has a tendency to make an impression on the opposite page, as was generally the case with new books when compressed by the old method, which was to beat them on a large smooth stone with a cast-iron bell-shaped hammer weighing twelve or fourteen pounds. This required some skill so as to compress or condense the sheets without marking them with the edge of the hammer, and to give the paper a smooth polished surface. This process was very much improved some years ago by a rolling-press, consisting of two iron cylinders, mounted and set in the usual way at any required distance apart. A number of sheets, varying from six to fourteen, according to the size, being placed between two tinned iron plates, are passed through the rollers. This method not only renders the paper smoother than by hammer-beating, but the compression of the book is one-sixth greater, a very desirable object, inasmuch as the book-shelves will contain nearly one-sixth more books. These superior effects are also produced by the rollers in one-twentieth of the time required by the hammer. This method is now adopted for books that have been printed some time, in which the ink is properly set, and also for books that require rebinding.

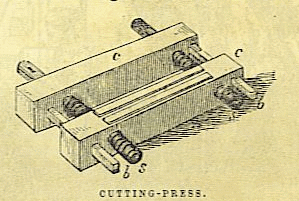

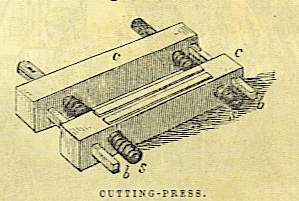

After pressing, rolling, or hammering, each book is collated, to see that all the signatures ran properly, and the plates, if any, are inserted in their proper places. The waste leaves are added at the beginning and end; the back and head are then knocked up square, and one side of the book is placed on a pressing-board of the size of the book itself, and another similar board is laid on the upper side of the book, taking care to let the back of the sheets project about half an inch between the two boards. The workman then grasps the boards firmly between the thumb and fingers of the left band, and lowers them into the cutting-press, which consists of two strong wooden cheeks c c, connected by two slide bars b, b, and two wooden screws s, s. The use of the two guide: on one of the cheeks will

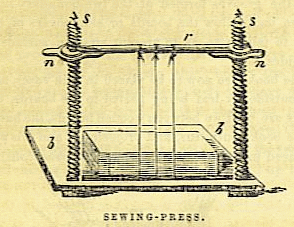

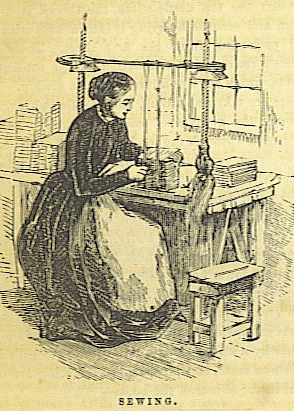

be explained hereafter; but it maybe remarked that when these guides are not wanted, the press is turned completely over, so that these guides may be at the bottom, and out of the way. When the sheet: are lowered between the cheeks c c, the press is screwed up tight by working an iron bar in the heads of the screws. The man then passes a tenon saw across the back of the sheets, so as to make a number of grooves, according to the size of the book, for the reception of the cords or bands for holding the threads in the sewing. and also for securing the boards which are to form the side covers. The number of bands depends upon the style of binding or method of finishing the book ; boarded books, or books bound in cloth, have only two bands. But in the better descriptions of binding, 32mos. sometimes have three bands; 16mos., 12mos., 8vos., and two-leaf 4tos., have four bands; royal octavos and whole sheet 4tos., five bands; and folios from five to seven bands. In addition to these grooves for the bands, a groove is also formed at each end for the catch or kettle stitch. Supposing a book with two bands is to be sewed, it is taken to the sewing-press, which is a stout flat board b b,

This press is arranged for three hands; but for the sake et

simplicity. the description refers to two bands.

containing an upright screw s s at each end, supporting a top rail r, which rises and falls on the screws by means of nuts n n. Attached to this rail are several cords corresponding with the grooves sawed in the back, and these cords are secured by being fastened to brass keys, one of which is here shown, passed through the aperture in the bed of

the press, while they are tightened by turning the nuts it it. so as to raise the top rail. The book to be sewed being placed on the board b, with the title uppermost, the sewer first takes the tly-leaf, or end paper, if such there be, or sheet A of the book, and turning it over so that the title-page may lie with its face on the board, she places the grooves in it so as to correspond with the stretched strings or bands. She then passes the left hand into the opening of the sheet, and with the right pushes the needle through the right hand kettle-stitch : the left hand receives the needle, and returns it out through the first groove above the stretched string: the right hand draws the needle completely through, and passes it through the same groove below the stretched string; the left hand takes the needle and passes it through the second groove above the string, and the right hand returns it below the second string; and lastly, the left hand returns the needle through the bottom kettle-stitch. The thread is then drawn so as to lie evenly in the angle of the sheet, a small piece being left projecting through the back at the top kettle-stitch. The sewer then takes the second sheet, and turning it over upon the first, inserts the stretched strings into the sawed grooves at the back.

She passes the needle through the bottom kettle- stitch, and proceeds as before, passing the needle in and out round the bands, only proceeding up the sheet instead of down. When the needle comes out through the top kettle-stitch, the thread is drawn tight, and secured by tying it into a knot with the end projecting from the first sheet. These two sheets form a sort of foundation for the subsequent sheets, which require a less elaborate sewing. Two sheets are taken at a time, and the thread is drawn through the grooves of each alternately : passing the needle through the top kettle-stitch of the lower sheet ; then out above the first band; then into the upper sheet below the first band ; then out above the second band; then below this band into the lower sheet ; then out through the kettle-stitch of the lower sheet ; and, lastly, this lower sheet is secured to the previous sheet by passing the thread round its lower kettle-stitch. Two more sheets are then taken, and in this way the sewing is continued with great rapidity. When one length of thread is nearly exhausted, another is taken, and joined to the former by a knot. This kind of sewing is called op and down work, and presents the following arrangement in the sheets of the book-

the sheets showing two threads and one thread alternately, as the reader will find by examining any boarded book, or a book bound in cloth. When the sewing of one book is completed, the thread is secured at the kettle-stitch, and cut off. A second book is sewed upon the first, upon the same bands, until the press is full. The bands are then loosened by slipping off the keys, and the books are separated from eac-h other by severing the bands, care being taken, for some descriptions of binding to be noticed hereafter, to leave a sufficient portion of the bands projecting on each side of each book for the purpose of securing the boards.

There are various kinds of sewing, depending on the size of the book and the style of the binding. The commonest kind of sewing, such as we have attempted to describe, is called zewing two theets,

up and down work. In some kinds of fine binding, the sheets are sewed nil along, and only one at a time; that is, the thread is passed round every band, so that, supposing there were three bands, the sewing in every sheet would present the following appearance:

![]()

Where it is an object to make the book superior and stronger, fine silk is used, instead of thread. To prevent injury to the book by sawing grooves for the bands, which cause the book to wear out much faster – for the holes thus made gradually enlarge in size until the book falls in pieces – a method of sewing is adopted without any grooves, tapes being used instead of strings. The only holes made in – the sheets by this method are those of the needle, which is passed in and out above and below the tapes, and the sewer forms her own kettle-stitch with the needle.

This kind of sewing is shown above. It requires more care than the former to keep the sheets even, and when well done the effect is excellent, for by this plan the book opens flat at any part, the fold of the sheet starting up fully to view when the book is opened. This style is called flexible binding.

When the books are folded and sewed, they pass from the sheet-room to the forwarding-Covering. The forwarder first prepares the linings for his book, which are made of fancy or enamelled paper; then, if the book is a stout book, for instance a quarto Bible, he makes his boards, which is done by pasting two or three pieces of the proper size together and pressing them. His linings are then pasted on his books, which are first glued, then rounded and backed. The operation of rounding the back is done by placing the book on its flat surface, and drawing the back on one side, gently tapping it with a broad-faced hammer: the book is then turned over upon its other surface, and the operation repeated, by which means the back is brought into a convex form. Each book is then placed separately between a couple of boards, with the back projecting, and is thus lowered into a screw-press, which is screwed up tight. The workman then, by a succession of blows, applied somewhat obliquely up and down one side of the back, depresses that side, and causes a ridge to project over the board. He then repeats the operation on the other side, by which means the back is depressed at the two sides, and is raised in the middle; a few gentle taps in the middle, and some finishing blows at the sides complete the rounding, and its effect is to form theside edges into a concave groove, the concavity or which corresponds with the convexity of the back, and the grooves formed at the two boundary lines of the back allow the boards or side covers of the book to fall in so as to present an even surface at the sides.

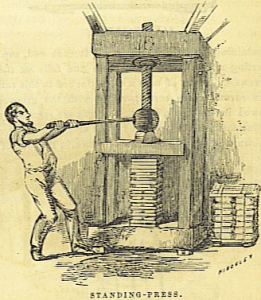

The books are now to be placed in thin cases, and the outside fly-leaf being pasted to the boards, the books are built up between wooden boards, the backs of the books outwards, and projecting; and this pile is placed in what is called a standing-press, consisting of a well-oiled iron screw working in a nut, and the upper bed of the press is screwed down with great force, by means of an iron bar inserted into the inverted head of the screw. To economize labor, the pile, which constantly varies in size, is made to rest upon a number of boards, which diminishes the distance between the upper and lower beds of the press. There the books are left for some hours to undergo the requisite compression.

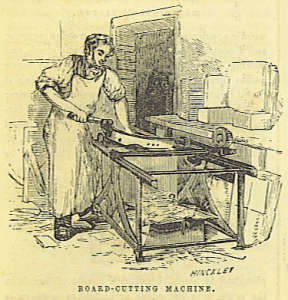

The mill-boards, which form the solid substance of the cases, are supplied to the binder in sheets, varying in size from 17.25 inches by 14.25 for the smaller sizes, up to 41 by 31 inches. The binder cuts up these sheets to the required size with great precision and rapidity, by a machine constructed for the purpose.

It consists of an iron frame, one- half of which is covered with a horizontal plate, or table, for holding the board. At the inner edge of this table is a holdfast, or bar of metal, extending across the frame, moving on a hinge at the opposite side, and connected by a hinged lever on the near Fide with a treadle. The lower surface of this bar is furnished with file teeth for holding the board fast. Just beyond this holdfast is a straight, fixed bar, with a square cutting edge, and by the side of this is a curved bar, or knife, mounted on an axis, and balanced by a weight at the further side, and furnished with a handle at the near side. The edge of this curved bar forms, with the fixed bar, a pair of shears for cutting… the boards. The gauge being set at the proper distance, the board is placed flat on the table, and its rough edge is first cut off. This is done by sliding the board along until the edge just projects beyond the shears. ‘ The man then puts his foot on the treadle, which brings the hold- fast down, and secures the board ; he next forces the curved blade down against the fixed blade, which cats the board to a clean, smooth edge. Then, releasing the board by lifting his foot off the treadle, and raising the knife, he passes the board up to the

gauge, which is furnished with an edge or chamfer, and stops its further progress: the board is cut through as before, the piece falling into the bin beneath. In this way, the board is cut up into three or four long strips, the other long edge, nearer the left hand, being cut off while it rests on the table. A number of boards being thus cut up, each strip being sufficient for two, three, four, or more boards, the strips are again passed through the shears, and cut to the proper size of the books they are intended to cover. Such is the precision of this machine that, when all the pieces thus cut are piled up and knocked together, they appear to form a solid parallelopipedon, with perfectly sharp edges, in consequence of all the pieces being of the same size.

The cover of the book may be of leather or of cloth; but, in either case, it is ornainented at the back and sides with a pattern inclosed within a figured or flowered border, with different toolinv and devices for the back, and blank borders for the gilt lettering or other ornaments. These are stamped, by means of certain presses, varying in power, with the material to be embossed. The dies are formed either of steel or brass, the latter being the more common. The dies are cut or chased by hand; but, for some patterns, consisting of regular curves, they can be more economically turned in the lathe, in which case brass must be used. The counter die, for embossing. which is attached to the upper bed of the press, is formed by the man who manages the press, by gluing a number of pieces of mill-board together, and gluing them to the surface of the lower bed. By turning the arms of the press round, the lower surface of the mill-board is brought up with amazing force upon the metal die, and the softer material takes the impression of the harder. The man then cuts and trims and adjusts the counter die, every now and then taking impressions on a paper; and when he is satisfied with his arrangement, he proceeds to emboss the leather pieces cut to the proper size for covering the book.

Every piece of leather requires to be passed three times through the press-once for the back, which is of course of a pattern different from that of the sides, and once for each of the sides. If the two sides are of the same pattern, the man embosses all the leathers on one side-say the left-and then, re-adjusting the die, embosses the other side.

Cloth covers are embossed after the boards are inserted. The cloth, which is now consumed in such enormous quantities in bookbinding, is manufactured for the purpose. The cloth is cut up to the proper size of the cover, an extra quantity being allowed for the overlap within the boards. The cases are then made up, with great rapidity, by two men, one of whom covers the inside with a layer of glue, and then places two mill-boards in their proper position on the cover, so as to form the stiff sides, the space between the two depending. of course, on the thickness of the book. He then turns the cover over, and rubs the cloth firmly down with a cloth- rubber, shaped something like the stone muller used in color-grinding, lie then tosses the cover to a man, who places a strip of paper or canvas along the inside of the back between the two boards, and then folds down the projecting edges of the cloth over the boards, smoothing them down with the edge of a fiat piece of stick with a blunt point at each end, and then drawing the point of the stick down the boundary lines between the back and the sides. The two men complete about one hundred covers in an hour.

When the covers thus formed are perfectly dry, they are embossed and gilt. The ornaments which are simply produced by pressure are called Wriddamping, and, when done by hand, blind-tooling; while the gilt ornaments or lettering are called gold-stamping or gold-tooling. The machines employed in both descriptions of ornament are called stamping-presses, and they do not greatly differ, except in power, from the fly-press already described. The ornamental pattern for the back or sides is cut out in a thick plate or block of brass, and is fixed in the upper bed of the press by means of a dove-tail joint. This upper bed is furnished with a cavity containing a gas-pipe, with a row of jets for heating the die by conduction of heat from the upper bed. The cloth covers are inserted within metal rules, which serve as a gauge, by a man who sits before the press, while another man turns round with great strength a large fly-wheel, whereby the lower bed is brought up a few inches upon the case in the upper bed, and embosses the impression. When the eases are to be gilt, it is first prepared with a thin layer of ovalbumen or white of egg, called glaire; after this, the gold-leaf is lail on and the case is then passed through the press as before.

In gilding, the designs are often made up of many different small stamps, according to the taste of the stamper.

As the covers are removed, they are taken by a boy, who wipes off the superfluous gold with a piece of thick rag, which thus gradually absorbs the fragile leaf, and, in the course of two or three months, this rag is so valuable that it is sold to the gold refiner, who burns it in a covered crucible, and thus recovers the precious metal.

The covers thus formed are next adjusted to the books, which we left in the standing-press. The covers are secured to the books by pasting the waste leaves on each side of the book to the boards, and to conceal this arrangement as well as the uncovered parts of the boards, and also to give a neat finish to the book, some colored paper, called lining paper, is pasted in. The books are lastly put into the standing-press for a few hours, and may then be said to be finished.

We have thus traced the various processes concerned in binding a cloth-boarded book. They consist of gathering, folding, and sewing the sheets; gluing and rounding the backs ; cutting the edges; making, embossing, and gilding the covers ; and, lastly, securing the covers to the books.

In a large establishment, such as Messrs. Lippincott, Grambo, & Co., the whole impression of an octavo work, consisting of one thousand copies, can be done up in cloth in the course of about ten hours; in which case, however, the cloth covers are prepared a day or two before, all the information required for the purpose being the thickness of the book, which is known by stating the number of sheets contained in it. The title and the style of ornament, color of the cloth, are also determined. A thousand covers or cases can be prepared in one or two days. The book itself can be folded, stitched, glued, and rounded, the edges trimmed, and the book mounted in cases and pressed, all within ten hours. This is, indeed, an extraordinary example of the power of numbers of skilful workpeople, and the effect of a refined system of division of labor.

The method of binding thus far described applies cniefly to those books which are issued in large numbers, and whether the covers be leather or cloth, there is no very great difference in the methods adopted. In leather bindings, such as in Bibles and prayer-books, the edges, instead of being trimmed with a knife, as before described, are cut throughwith a plongh, so that there is no necessity for cutting open the book before reading it.

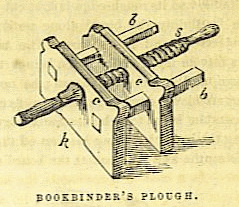

The bookbinder’s plough consists of two upright cheeks of wood c c, connected together by a wooden screw f, and a couple of guides b b, fixed into one cheek, and moving in square holes in the other.

The screw passe: through both cheeks, so that by turning it round in one direction-the cheeks are brought nearer together, and, in the contrary direction, moved farther apart. Into one of the cheeks at k is fixed a cutting-knife, a double-edged, pointed blade, of which two forms are given.

The book to be ploughed is placed between a couple of boards in the press, with the edges projecting as much as is required, and one of the cheeks being placed in a groove of the press, the point of the knife is brought up to the boot, and moved backwards and forwards against it, the workman at the same time giving the handle of the screw a twist, which advances the knife forward until the cutting is completed. The white edges of the book in common binding are then sprinkled, whereby that speckled or mottled effect is given to them, which prevents them from soiling, and also improves the appearance of the book. This is done by mixing up some colored chalk, umber, Venetian red, or ochre, in a little size and water, and dipping a brush into the mixture, so as just to wet the bristles; the man holds a long piece of wood a few feet over the books, and beats the bristles of the brush against it, which causes a shower of minute drops of color to rain down upon the edges of the books, a number of which are set up together for the purpose. When the desired effect is produced on the top edge:, the books are turned over, and the bottom edges are treated in a similar manner, the man turning up one of the finished edges, every now and then, to see that he is producing the same tint of color at the bottom as at the top. The side edges are done in the same way, and the color is fixed by placing the books in the bench-press, and passing an agate burnisher over the edges, which produces a high polish, and prevents the color from being removed by ordinary use. By these simple and expeditious processes, a cheap and useful ornament is added to the books.

In the better class of binding, as in whole-bound calf, gilt lettered, with raised backs, the boards are added after the gluing and rounding of the backs, for which purpose the sewer leaves small projecting pieces of string bands. The boards being cut to the proper size, a couple of holes are made in each board with a brad-awl, opposite each band, and the string being passed through these holes is secured with glue. In a book of three bands, the boards are held by six strings, three on each side, and each board is, of course, pierced with six holes. The books are then put into the standing-press for a few hours, after which the edges are ploughed, the

boards being slightly depressed below the edge to be cut off, the strings allowing them a little play before the cover is put on. In cutting the side edges, the workman takes care to preserve the concavity produced by the rounding, for which purpose he flattens the back by passing a flat tool between the edges of the boards, which are allowed to hang down loose, and the back. He then places the book between a couple of boards, grasps it tightly, and withdraws the flat tool : then lowers it into the press, and screws it up tightly. By tints flattening the back, the edges become flat also, and when they have been ploughed, and the book is taken out of the press, the back starts into shape again, and the side edges become concave. After this, the edges are gilt or marbled. In gilding, the book is secured between a couple of boards in the press, and the edges being covered with glaire, a layer of goldleaf is laid on, and the agate burnisher, being well rub bed over every part across the edges, secures the goldleaf, at the same time giving it a beautiful polish. When all the edges are thus gilt, paper is wrapped round them, to prevent them from getting soiled. When the edges are to be marbled, the books are sent out to the marbler’s, who produces the effect of marbled paper by the following contrivance: A trough about two inches deep is filled with clean gum-water. Various colored pigments, ground in spirits of wine, and mixed with a small quantity of ox-gall, are thrown upon the surface of the gum-water, and disposed in various forms with a quill and comb, according to the desired pattern. This being obtained, the book is tied between two boards, and the edges being dipped into the trough, the floating colors become attached cold water is then dashed over the edges, which sets the colors, and brings them out clear.

The book is now ready to receive the heaband, which serves as a finish to the top and bottom of the sheets, and assists in keeping the upper and lower parts of the hollow back in shape, when the book is closed. The book, still in the rough boards, is fixed by one corner in a small portable screw-press, and a small strip of mill-board, placed on edge at the back, is secured by passing a needle and thread two or three times between the leaves through the solid back and over and under the small strip; the thread, which is generally of silk or cotton, two or three colors being sometimes used, is then twisted or plaited over the strip, and when about a third or one-half is covered, it is further secured by a few stitches through the solid back. The plaiting or covering is then completed, and is secured as before by sewing through the back. The superfluous portions of the strip are then cut off. This description of headband is called worked; a commoner description, called stuck-on, is a piece of striped or colored linen, inelosing a piece of cord, stuck or glued to the back of the book. The bands or raised projections at the back of the book are formed by gluing strips of millboard, leather, or cord across them.