In many instances, carriers either on the belt principle, the continuous pocket or the slide, have been installed and are found to be productive of excellent results.

In disposing of the waste stock from the cutting machines, gravity has been called into use, and the various waste is shot down steel tubes to the basement, or to outside of the building, where the material is baled and shipped.

With the rapid increase of electrical installations, the use of individual motors, and the placing of machines at points conducive to scientific results, has come the necessity for better lighting facilities, and here we find electricity superseding gas light, making increased facility and less risk for the worker.

In the sheet end of the bindery, the platform and elevating truck principle was inaugurated some years ago. It has been improved to the extent of eliminating double or triple handling, unusual energy in raising or lowering the trucks and in transporting the loaded platform from one point of the plant to another. Binders throughout the country are realizing that the platform system with the elevating truck principle, is absolutely the best handling and storing method. i

A useful adjunct to the platform system is the “Tenement House Signature Truck/’ which enables the transporting of coated paper signatures, as well as other signatures handled in bulk, without piling and interlocking the piles on the platforms. There is also a manufactured truck which acts as a protection for carrying aluminum or brass-bound press boards.

To sum up in a few words the result of modernizing and standardizing the bindery, it should be said that flexibility of plant is the one aim and result. With flexibility, a plant is not dependent upon any one class of work for its upkeep, but a plant that is not flexible requires time to change from one contract to another, and to adapt its organization and equipment to the requirements of the new work. This takes time and costs money.

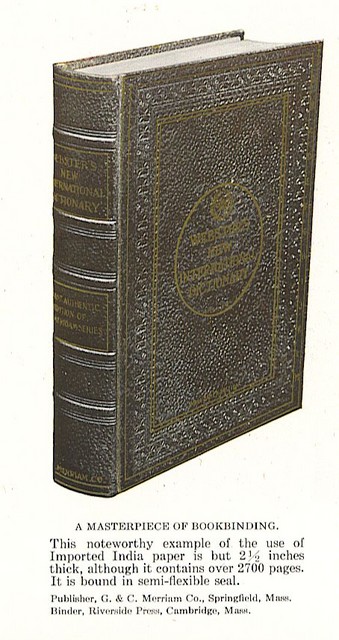

In the early part of this article it was intimated that the adoption of India paper for reference books as a commercial agent in reducing bulk, had been productive of newT ideas, processes and styles in the various bindings. It is now possible to combine in one volume the entire contents of two or more volumes as printed on ordinary paper, or if not combining volumes, to produce individual volumes of one-third or one-quarter the former bulk, and the use of this paper and its adaption to flexible bindings has brought about a book that is absolutely limp.

But in order to produce satisfactory bindings with the India paper it has been found necessary to resort to the French tip with inserts—that is, the stubbing of the insert around the signature usually with a thin bond guard; the guard and plate not pasted to the signature, but sewed in. The one great difficulty in working India paper is its aversion to moisture. Other difficulties have been encountered such as the dog-earing of pages; the winding of signatures causing pages to be folded at right angles inside the signature; the starting of signatures after the book has been trimmed and before it was completely bound, and like defects. These have been overcome, and today the India paper binding represents one of the highest results of the binders’ ingenuity.

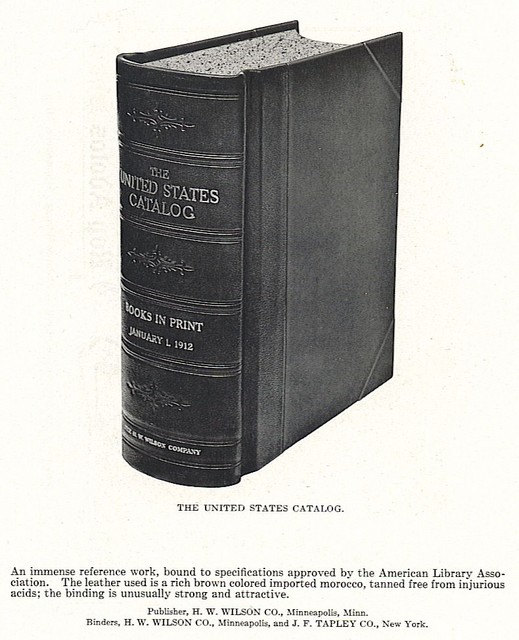

Outside of the India paper bindings, great strides have been taken in the production of durable bindings. The American Library Association specifications which have been referred to previously, have aided the binder and publisher in this respect.

With the return of subscription bindings in individual volumes and sets, came the demand for gold work at low cost, and with the use of the gold roll machines, some very beautiful designs have been worked out which have been produced at low figures. Gold roll machines have also superseded in many instances hand-laying methods.

The loose-leaf idea for catalogs continues much in evidence. Some of newer ideas in binders are the ratchet catch, the snap lock, and the double post binder, which permits the inserting of loose leaves without removing any sheets from the book. A new idea in loose-leaf cataloging is that of the portfolio, in which the loose sheets are held in place by the flaps, and the cover tied with tape.

Some very unique ideas in inexpensive bindings have been worked out through the combinations of cover papers made up in the manner of the regular cloth cover with cloth backs and paper sides, or two harmonious colors of paper. In the pamphlet with its many combinations, sewed or wired inside, with full, parti or combination paper covers, unusually fine results are obtained. For the heavy pamphlet, sewed or wired, a single end sheet stubbed around the first and last signatures and the cover drawn on solid to be cut flush or to overhang, has been found desirable. Concerns that issue catalogs of goods on which prices fluctuate requiring the issuing of a new catalog every six months, or year, have adopted the sewed pamphlet with ordinary end linings of cover stock pasted, a cloth strip down the back solid to back and linings, and with paper sides usually of double thick stock, treated in an artistic manner by printing and embossing.

For catalogs of few pages printed on coated stock which will not bulk sufficiently to give a backbone to the book, the expedient of inserting a thin strip of binders7 board instead of back lining in the covers is followed, thereby giving a perfectly flat back to the book and permitting stamping.

The laced-in book in the old hand-bound style, has almost entirely disappeared, and in its place has been developed the combination-bound book sewed upon tapes, the tapes extending to the joint, cloth joints, and whipstitched end signatures, producing the desired smooth outer joint of the old laced-in book with boards flush to the joint at the round, and without the old objectionable knobs where the bands were formerly laced through the boards. Needless to say, this is less expensive, and really produces a finer piece of binding than the old-style hand work. This actually produces the appearance of hand work, with much of the hand work eliminated.

For large reference books, a new style has been evolved using unsplit leathers and allowing a wide joint between the boards and joint of the book at the round, permitting the covers to be brought back face to face when opened. In this particular type, as evidenced by the Century Dictionary, the books are sewed on four tapes of special strength. The tapes are concealed by an ingenious method, using tag stock and a canton flannel back lining. The tapes, canton flannel, crash and concealed cloth-joints are brought between boards in a manner which gives exceptional strength. One who has not examined a volume bound in this style, would think for a moment that this would cause a bulky appearance on the inside of the covers, but the entire process has been handled in such a manner that were it not for the exceedingly strong appearance of the book, the peculiar nature of its construction would not be noticed.

It may be said in general, that the tendency is to produce better bindings than heretofore. Materials which are used, and which will be mentioned later, are of better quality. The workmanship is consistent with the quality of material, and the final result as shown by a majority of the volumes published in this country during the past year, shows a decided improvement.

The two-piece corrugated carton retains its popularity as the best medium for shipping heavy volumes,, For exceedingly heavy volumes, these are further reinforced by an inner protection running around the book and preventing the breaking of the corners while in transit.

A new feature in shipping cases is now obtainable. A fibre case made of stock sufficient to carry 100 pounds and permitting the packing of books in units, simplifies the shipping of individual lots.

A new idea in magazine and light book shipping, is a cardboard carton which comes flat, folds over upon itself with ends inserted, and through two small holes at either end, a small tin clasp comes through and locks. The jute envelope with turned-in end and flap, and with cord attached for sealing, is also popular. In place of the old mailing tube, there has been brought out a new wrapper which consists of a manila wrapper shaped and cut to varying sizes, with a protection of thin board inside, and with a cord and clasp at the finished end. This has been found useful for mailing samples of cloth, specimen sheets of printing, binding impositions, magazines and periodicals. In some instances, a flap is added to this wrapper, which permits the tucking in after rolling, thus preventing loss. With the advent of this product, the old mailing tube is destined to become obsolete.

It is interesting to note that after having spent much time and care in producing an attractive binding, more attention is being given to its proper protection and delivery.

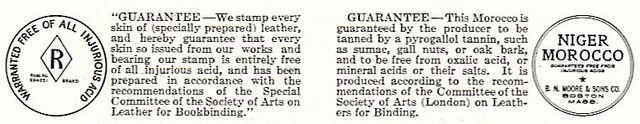

Each year sees new ideas in materials, and during the past year many developments have been made in the various materials used in bookbinding. Principal among these is the introduction of leathers tanned and finished free from injurious acids. Leathers which were formerly imported are now being produced to a great extent in this country. R. Neumann and Sons of New York, are now producing leathers which are as free from injurious acids as it is possible to obtain. This has also been taken up by Benjamin N. Moore & Sons Company of Boston, who are specializing in Niger Moroccos. We reproduce for examination the marks which are now appearing on domestic finished

Niger skins, and on the imported acid-free leathers. It is safe to predict that within the next few months, we shall see developments in leather producing which have never before been heard of.

The Arabian morocco which is shown in one of the illustrations given, is also an acid-free tannage.

Among the less expensive leathers, some new designs have be€;n brought out in the embossing of skivers and buffings.

It may be said that more of the better grades of leather are being used at the present time than were ever known in the past, unless we go back to the earliest times of binding when the curing and tanning of the hides extended over a period of many months, and each particular skin made the very best.

There has been considerable advance in the paper line towards producing papers with grains the correct way for binding, and more especially in cover papers, without the use of sulphite. If a book is to have a paper cover on which gold or imitation gold is to be stamped, it should be ascertained if the cover stock is free from sulphite. It is also true that printing upon stock and binding with stock that is free from sulphite, should the wrapper which is put around after binding have sulphite in its make-up, the gold or imitation gold will tarnish. This also applies to cloth or leather bindings wrapped in material which contains a large amount of sulphite.

A very good attempt at securing a bugproof cloth has been made by the Bancroft people. While their experiments, as well as the experiments of others, are not entirely completed, it is possible that within a year or two, we shall have a cloth which is impervious to insects.

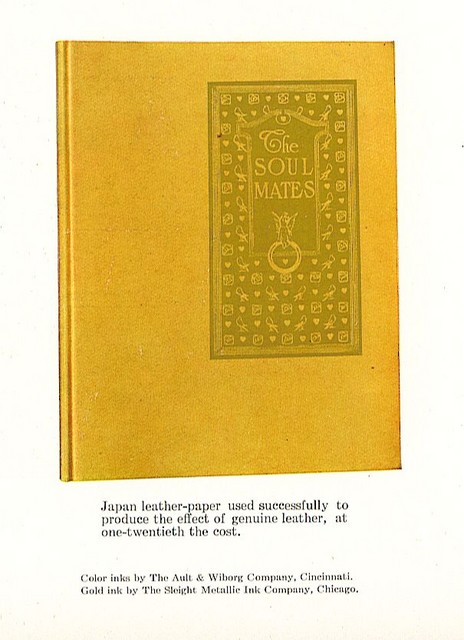

A varnish which is used in many libraries for coating books used by children, has been found to be useful as it does not crack, repels moisture and will not be attacked by bugs or insects. The one preventive of its use, however, is the expense of varnishing. Unless a cover, as shown in one of the illustrations, be made of paper varnished before binding, the expense is prohibitive.

Some very attractive new cover stocks have been brought out and have been found to be very popular. There are also many new things in imported Japan and Italian papers in colors and finishes; also in Japan vellums which are being found useful in binding.

In the line of stamping materials, there have been few developments. A very satisfactory leaf has been brought out by the Becker people,, its one disadvantage being that it must be brushed off immediately after stamping. It has the added advantage, however, of being of sufficient weight and clinging tendency and at the same time inexpensive, which permits the laying on of the leaf at one side of the stamping press, as fast as the operator can feed. By immediate brushing and rubbing off afterward, very good results are obtained. The standard Oeser and DeJonge foils continue popular,,

A new artificial gold has been brought out by the DeJonge Company, which can be purchased cut to given size at so much per square inch,, This is found of advantage in large contracts where the waste from regular size imitation gold would be prohibitive.

Many new designs have been brought out in cloths, among them the E pattern or linen-finish Becker cloths, the YR pattern in the Winterbottom cloths and the LW pattern Holliston cloths. Binders are finding the many patterns in the Holliston, Interlaken, Winterbottom and Bancroft cloths useful, where the ordinary T patterns cut to a disadvantage. Using an all-over pattern, cloth may be cut either way and considerable saving results. The Wiboco cloths are also used in many instances where an unusual result is desired. The imported Imperial cloths are also popular.

The manufacturers of bookbinders’ materials, particularly leather and cloth, seem to realize the progressive spirit which is permeating the entire trade, and are striving to keep abreast of the times by producing the very best materials in the newest colorings and designs.

It is needless to enter into a long discussion of the question of artistic combinations and attractive designs now being used in binding. Where buckram (particularly the Library Buckrams) is used, some very beautiful effects are being obtained by embossing patterns which give a polished finish to the sunken portions of the cloth. Japanese leather papers are used extensively to imitate leather on inexpensive bindings and the combinations are very desirable.

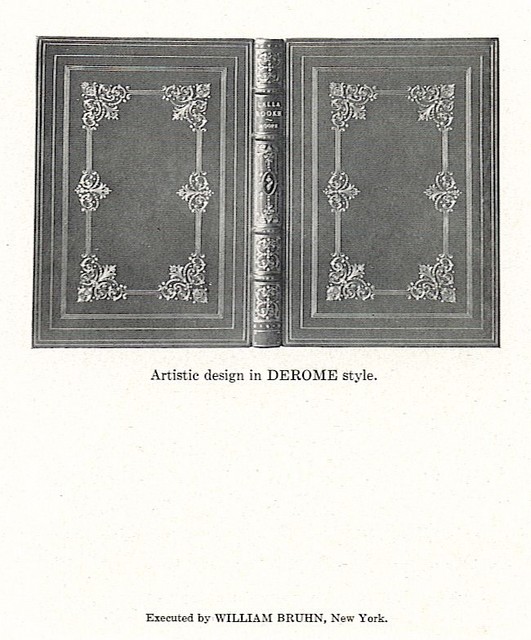

More attention is being paid today to the designing of covers which shall reflect the character of the book. The carelessly prepared design is being eliminated and it is noted that there has been a general return to the old frosted and stippled effects in gold work, which for many years were discarded. New designs employing these effects are exceedingly beautiful. The tendency is in general to have less elaborate designs, in many instances more delicate and with less of display.

In pamphlet work there is an unlimited field for the artist. We find it reflected in the hundreds and thousands of catalogs which are put out each year with paper covers either in ink, ink and embossed, or embossed effects alone. An unusual idea brought out this year by a subscription house is that of a stretcher with all of the advertising material pertaining to each subject upon a separate leaf. The stretcher worts both ways and contains besides the illustrated matter, photographs of the volumes taken in the homes of the rich and the moderate classes, together with completely stamped covers of the various bindings, and a sample signature of the India paper on which the volumes are printed. This entire stretcher when folded up is about the size of an ordinary 9 x 12 book, with a neat leather cover and a button snap fastener. The idea is one which has never before been developed, and without doubt will prove to be an excellent selling medium.

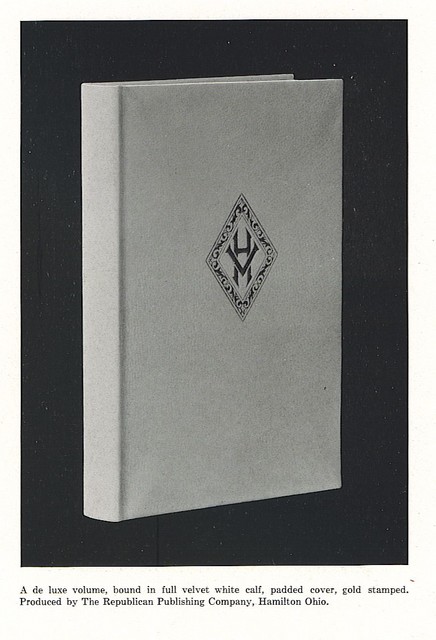

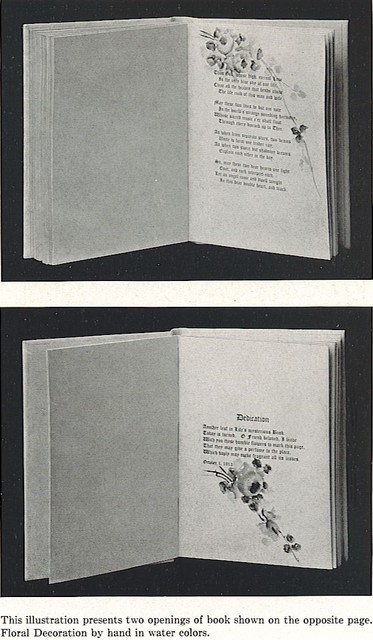

De luxe work continues in the usual beauty of designs and finish, and it is interesting to note that genuine levants and Turkey moroccos are being used in increasing quantities, although de luxe work is not as active as it was formerly. We are illustrating some of the beautiful results which are obtained through careful designing, tooling and inlaying of the covers.

Believing that all binders are interested in the proper organization and management of that ‘ ‘treasury of the bindery”—the Stock Room—we present for their assistance those things that have been evolved by careful analysis of general conditions and application of principles of scientific management to the stores department. We present it in a form which will enable those not entirely familiar with developments along these lines to assimilate the ideas readily and apply them in their own plants if they so desire.

The fundamental object of scientific management is to so arrange routing, that a job begun as a unit at a given time will end as a unit, though in different form, at another given time. This insures a maximum amount of production and affords to the worker that incentive which should always be present— the opportunity to earn a maximum wage or bonus which is impossible unless routing is carefully and scientifically arranged.

Among the several laws which enter into proper routing, the stores exercise a very important function. A stores system is indispensable to routing. Goods and raw materials must be of proper quality, which is to say, that they must have passed the standards set for them by the inspectors; there must always be sufficient quantity on hand; they must arrive at the work place in a given condition and be subject to the least possible amount of waste through imperfect quality; in other words, every possible hindrance to the smooth passage of a given article through its process of manufacture must be removed. All of these things are quite obvious. The more interesting side of the question lies in the method of insuring proper conduct of the stores department.

The functions of the stores department are those of receiving, handling, accounting and purchasing. The location of stores is the first problem which meets with attention and it is pretty safe to say that stores never belong in the manufacturing departments, with the exception perhaps of stores required for jobs in process, and stores which are regularly required at points in manufacture.

If stores are not kept in one especially designated place, each worker who handles them becomes his own balance clerk. No accurate inventories are possible and it follows that there is constantly multiplied duplication of work, both physical and clerical. Raw materials and other articles which come under the general head of stores should then be kept in a definitely located place and in one room, if possible. If not, at least on one floor, which should be so located that by means of modern transportation systems, deliveries may be made with the shortest possible hauls to all points in the plant.

The stores themselves are under the supervision of the stores keeper, who has charge of the actual handling of the materials, their distribution and inspection. The balance clerk is a functionary of the planning department, and his duty is to maintain the balances; to set maxima and minima; to see that the quantity of goods on hand is never too little for the average demand, nor too large, tying up money unnecessarily; to check the balances in the stores department by a systematic daily inspection of the quantity of goods on hand and the quantities as shown by the tags which hang on the stores bins, and finally, to draw off his balances at the end of each period so that his records shall balance just as a ledger is balanced. The third functionary is the receiving clerk, who is sometimes one with the stores clerk, and the fourth, the move man or men, who, acting on move orders issued by the planning department, convey materials from the stores department to the machine or work place.

Having located the stores department, the next move is to establish a series of standard bins with standard aisles and to index these by letters in groups of four. The first will show the letter of the room; the second, the section; the third, the row; and the fourth, the tier. The “A” room may always be located as being one nearest the northern end of the building, so that symbol AACB would indicate that that particular article may be found in the “B” tier of the “C” row of the “A” section of the “A” room.

Before ordering stores, the most careful attention must be paid to standardization, for without it, all money spent in the development of a stores department is practically thrown away. A careful inventory of all the articles in use, with their makes and qualities, must be made, and by a scientific study, standards selected which must be rigidly adhered to. It is not unusual for a company handling miscellaneous stores to cut down its stores expense from 40 to 50% by standardization. Nothing is too small to standardize and the items of pencils, erasers and other minor supplies often total surprising figures. When stores are received by the stores clerk, a tag is made out which is hung on the side of the bin in which that particular article is stowed. This serves as the store clerk’s running account of the transactions in a given article and the total carried at the foot of his stores tag must always correspond with the actual amount of the material in stock. A notification of the receipt of stores is sent to the purchasing agent in order that he may check his records properly, and the balance clerk receives a duplicate for entry on the stores balance sheet. The goods are then inspected to see that they come up to the standards set for quality, and acceptance or rejection follows. They are then stowed in an orderly and systematic manner in definite units so that they may be readily counted, and a neat stock room usually means an economical stores department.

The balance clerk establishes on his balance sheet the values per unit of each article of stores received and keeps a record, showing extension of the values, the quantity of goods on hand, the quantity on order but undelivered, the quantity assigned to definite orders, and the amounts which are available for general purposes. One of the notable advantages of this method is the check upon the accuracy of the accounts of the stores situation. The first check is the actual account upon arrival in the shop; the second is the periodic checking by the balance clerk who divides his total amount of stores into approximately three hundred parts, having a given number of articles for inspection every working day of the year, and each of these units is inspected and verified every day so that a perpetual running balance and inventory is maintained. Thirdly, the balance remaining on stores is entered on each stores issue sent out by the balance clerk, checked by the stores keeper and returned to the balance clerk. Fourth, as each lot of stores is used up the tag is sent to the balance clerk. Then there is the balance on the general books of the company, the checking of the original stores issues from the duplicate held by the balance clerk; and lastly, a neat store room, conduces to the more accurate keeping of accounts and decreased spoilage of stock.

Very little equipment and no complicated clerical machinery is required for the operation of the scientific stores system. It requires, of course, more organization than the old-fashioned method of each department having its own store room, but its importance as a cog in the wheel of plant efficiency can scarcely be over-estimated. No person in the organization excepting the balance clerk or one of his deputies has the right or authority to send out a stores issue. Thus responsibility is centralized. In this one department is assembled the entire situation as regards raw materials—from quantity, quality and price, to accounting, accuracy and apportionment. Waste is eliminated as it is the duty of the balance clerk to see that odds and ends are used up on orders as rapidly as possible, and accumulations of any kind are rigidly prohibited. Investment in stores is lessened and everything makes for efficiency so that what in many plants is still an eyesore, has come in some to be a joy to the owner, who can see his stock selected according to scientific standards; who can be sure that nothing goes into his work rooms which has not passed a pre-determined test, and he can walk down the aisles of his stock room and find everything in its place, carefully wrapped, clean, in short, a condition which wrill enable him to figure a tidy profit at the end of the year, instead of loss from surplus and over-stocking, simply by the application of common sense principles under the name of “Scientific Stores Keeping.”

Readers will recognize in the foregoing, provided they are familiar with the latest developments, the underlying principles of scientific management as it enters into its own in the stock room. Little need be said of the various machines now in use in that department. The most excellent method of operating machines in conjunction with the stores department is to keep the two entirely separate, and new developments in the equipment line have been covered previously,

It is gratifying when looking backward over the year’s progress to see the advance which has been made in every line connected with edition and de luxe binding. It can be said truthfully that the past year has seen an advance which surpasses any previous year. The condition of the workman is better, the organization of the employer is improved, business conditions are more stable, and the outlook for the new year is a bright one. There is but one forecast for the future, which is not as pleasant. The small binder is gradually being forced out. The larger binder with a plant now becoming flexible, is able to handle the smaller jobs along with his large contracts and is able to turn them out more promptly than the smaller man. It is therefore evident that during the next few years, we shall see fewer but larger binderies, and it is safe to assume that if we progress as we have in the past year, the binding industry will soon demonstrate its right to be classed among the ten great industries of the world.