CHAPTER I

Basic Principles of Paper Cutters

PROGRESS OF THE GRAPHIC ARTS from the handicraft of the ancient Egyptian picture writers through the unexcelled art of the printers of Gutenberg’s day, has resulted in the development of several processes which largely may be called exact sciences. Known facts and techniques, controlled materials and precision tools are combined to produce a standard result. Whether this science be letterpress, lithography, gravure, silk screen, mimeograph, or any of the several graphic arts processes, there exists a common problem of cutting the paper used.

Precision cutting and trimming machines of the present may be traced to the handicraft period when man first met the necessity of some means of making several sheets a similar size.

The earliest cutting machine was no doubt a sharp stone or a stick, then a piece of metal dragged across the parchment with a guide to keep the cut in a straight line. The sheet was simply held by the hand. and later the straightedge formed a clamp, also.

About the fifth century the important step of folding the vellum into leaves became the practice. The instrument which we know today as scissors or shears probably had a large part to do in these early operations. With the invention of printing and the multiplication of books, larger and stronger means were necessary to cut the sheets.

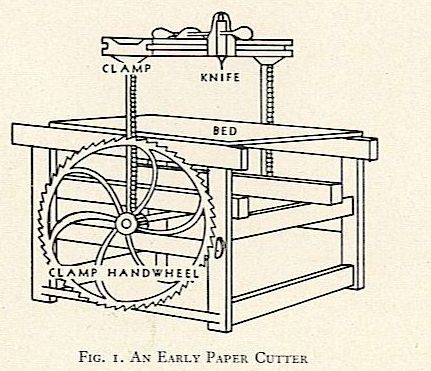

The earliest attempt to improve this consisted of a table with a framework of wood or metal above it, having a groove in which the knife could be worked, and a screw clamp to hold the paper.

Paper was clamped on the bed by turning the handwheel. When secure, the handwheel was locked with the ratchet teeth and the cut made by working the knife back and forth in its groove.

According to Gray’s historical account the first guillotine type paper cutter was produced in Germany around 1855. Descent of the knife through the paper was accomplished through a set of gears connecting the knife and a large handwheel. In a later improvement the knife was pulled through the paper by two cranks at opposite ends of a shaft parallel with the knife. The arms connecting the cranks with the ends of the knife were adjustable to control the stroke.

Other developments include power drives, hand and automatic clamping devices, adjustable back gauges, automatic measuring attachments and several types of safety devices. The present trend is toward the application of hydraulic power to drive the clamp, knife and back gauge. Mechanical construction of the machines is becoming increasingly accurate and durable to keep pace with larger productive capacities and closer tolerances demanded by modern press equipment. As the graphic arts become more specialized sciences, there is accompanying a specialization in cutting machinery. The field of magazine and book publishing, for example, has developed types of trimming machines suitable for that purpose alone.

Basic cutting principles.

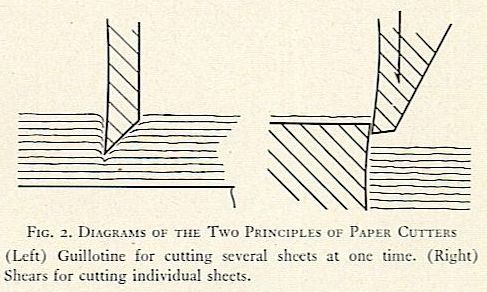

All paper cutting machines are based upon one of two fundamental principles: the shears, consisting of two blades passing each other in contact, edge to edge: and the guillotine, in which the cutting is accomplished by the descent of a single sharp knife.

(Left) Guillotine for cutting several sheets at one time. (Right) Shears for cutting individual sheets.

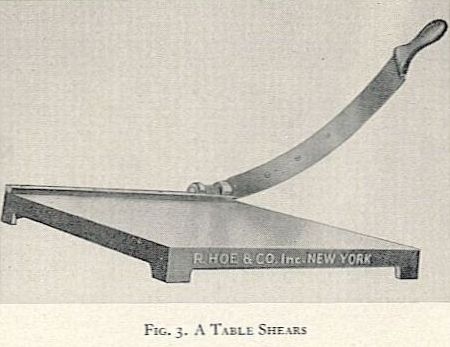

A simple cutting device illustrating the shears principle is the scissors. Figure 3 pictures another simple shears consisting of a blade bolted to the work table and a movable blade hinged at one end and held in contact with the first blade by spring pressure. The paper is held in position with one hand while the blade is lowered with the other. These machines are used by artists, photographers, schools and offices.

A similar shears is used by bookbinders for cutting individual sheets of compressed binder’s board. The binder’s shears is a metal table about 48 inches square with a blade of corresponding length attached by a hinge in contact ‘vith a blade bolted to the table. The paper is held by a clamp operated with a

foot pedal, leaving the operator’s hands free to lower the blade and catch the cuttings.

More complex machines using this principle are: sheeters, the rotary shears used to convert rolls of paper into sheets: and the Sheridan A-T single book trimmer.

Guillotine cutters are used where a number of sheets are to be cut to a given size at one time. A simple guillotine machine is the hand lever cutter, figure 4. The machine is made up of a work table with two solid sides and an adjustable back gauge, a clamping device engaged by turning the large wheel above the machine, and a knife connected to the lever at the right by a series of links. The cut is made by pulling the lever toward the operator’s left.

Although there are many complex variations of the guillotine cutter, each has these fundamental parts: work table, clamp, knife and power source. Guillotine cutters may be classed as follows: (1 ) hand lever, (2) power with hand clamp, (3) power with automatic clamp, (4) single knife trimmer, (5) three knife trimmer, (6) continuous trimmer. Each of these classifications has variations among the different manufacturers.