By RALPH FLETCHER SEYMOUR, CHICAGO

THE various branches of the art of bookbinding as practiced from year to year, show modifications which are due mainly to the introduction of new materials suitable for binding, to a gradual advance in the machinery used in binding books, and, to a less degree, show progress made possible by newly arisen practical necessities, or introduced and accepted because of some clever designer’s aptitude in his reassembling the old material into attractive new forms.

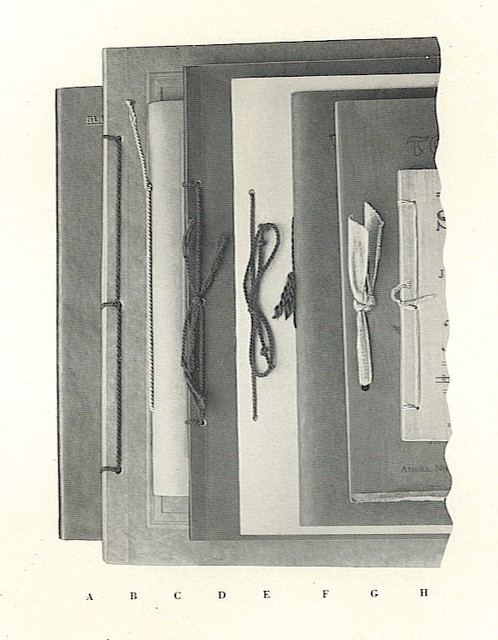

In view of this, it is only possible to summarize in a broad way the various sorts of binding now used and to give as well as possible an impression of the maximum to which they have progressed during the year. The most commonly practiced form of binding is that of booklet work, where wire stitching and silk tying, or both, are used, and the attractiveness of such work cannot depend on much besides the beauty of the stock and the charm of the design used.

Saddle wire stitching of cover to body gives the binding sufficient strength for ordinary booklets. Often small sized booklets of few pages are bound with silk floss without the saddle wire, but it is generally wiser to include the saddle wire stitch, even in small books.

Silk floss comes in over nine hundred different shades of color. Care should be used in selecting a color harmonious with the stock. Where the booklets run to considerable size or have a stiff cover, silk cord should be used in place of floss. This requires punching and costs more than the former, but the effect is finer. French booklets are usually bound with a plain knot near the top of the booklet and the ends cut off to about one-half inch in length. This is cheaper than the method we commonly use here of gathering the ends through the middle punch and tying in a bow knot, and looks equally well. (Compare the two ties shown in illustration Page 511.)

STYLES OF SIMPLE BINDINGS

STYLES OF SIMPLE BINDINGS

From left to right:

“A” is the ordinary saddle wire book,

“B” sewed booklet, scored cover, punched and tied with silk cord, the cord being gathered over the back-bone at each punch.

“C” simple French method of tying cord.

“D” side wire stitched book, tied with silk cord.

“E” saddle wire book punched and tied with silk cord.

“F” saddle wire book tied with floss.

When the floss tie is as small as this illustration shown, it would be better to omit the floss entirely.

“G” book punched and tied with tape.

“H” sewed book punched and tied with Japanese binding thread.

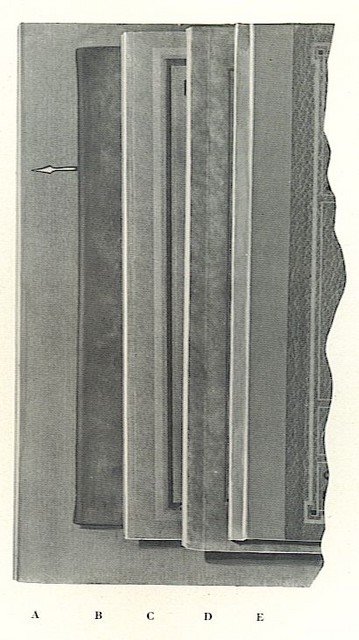

STYLES OF SEWED AND SIDE WIRE STITCHED BOOKS

STYLES OF SEWED AND SIDE WIRE STITCHED BOOKS

From left to right:

“A” sewed book with simple pasted cover.

“B” ooze leather cover pasted to back-bone and end sheets.

“C” inexpensive case bound binding cloth back, paper sides.

“D” screwed book with cover scored and pasted to end sheets.

“E” shows a double end sheet of fifty pounds antique cover double folded and lapped and screwed around the outside section with the cover in two pieces, and a strip of cloth over the back-bone. This strip of cloth is pasted between the cover stock and the end sheet stock. This is a good binding for machinery catalogs and books that are handled a great deal and has an end sheet sewed around the section which insures permanency of binding and by half of the end sheet being pasted up to the cover, it is practically impossible to break the cover off without tearing the book apart.

Larger booklets containing between forty-eight and sixty-four pages should be bound with either the side wire stitch or sewed, The side wire is the cheapest and is usually satisfactory. It is generally used for magazine binding. The cover is usually pasted on the back of the book. A booklet so bound, will not open as flat as the sewed book will and this constitutes the least desirable feature of this type of binding.

Sewed or stitched booklets offer many possibilities to the original designer in the way their covers are folded and pasted around the end sheets. Attractive end pages, pasted against the back page of the book sheets and also to the covers are usually desirable features in booklets which will allow of the extra expense. Overhung covers or covers folded inwards either around the first and last pages of the sewed forms, or inward against themselves (see one of the illustrations here shown) — also contribute to the attractiveness of the work.

There are occasions when the saddle stitched back is so thick that the center pages squeeze oil from the stitching; a piece or strip of re-inforcing cloth can be put on very quickly down the inside center fold and the sheets saddle stitched through; this will insure the catalog staying together. On side stitched or sewed books where end sheets are not used, a strip of cloth or paper, matching the cover stock, may be sewed on to the body between the first and second sections, at the front of the book and the last two at the back of the hook. This strip should be pasted on to the cover stock.

Where end sheets are used in sewed or stitched booklets and pasted to the cover, a more than ordinarily durable binding is secured.

Cover stocks for booklets are continually being improved and a great variety of colors, finishes and thicknesses are stocked by all leading paper houses. This condition adds greatly to the possibilities of booklet work. The most vital feature in the physical appearance of the booklet is that of attractiveness; and the design used on the cover, as well as the arrangement used in the binding is of great importance in procuring the maximum of efficiency. For this reason, good designs should be considered imperative and it is as necessary that a competent piece of work be done on a very simple cover as on a cover which has an elaborate design.

Automobile and railroad catalogs in particular, have taken advantage of the possibilities in attractive booklet covers and have set a standard design rather high.

Deckle-edge cover stock is improving, and if hand-made paper is possible, very little design is necessary, the stock itself usually proving more beautiful than a design printed on the same stock (thereby nullifying the exceptional quality of the stock). Several examples are shown of booklet work and while this field is a very broad one, it is our belief that more possible effectiveness is lost to the man who pays the bills in the production of careless designs and poorly thought out booklets, than any other department of bookbinding.

LOOSE LEAF SYSTEMS OF CATALOGING

Many printers and large manufacturers have been active in trying to devise an adequate system of loose leaf cataloging that will enable the manufacturer to reduce the expense of having to produce each successive year an entirely new edition of sales catalog. Many manufacturers have expressed doubt as to whether the loose leaf catalog system would be faithfully kept up by the recipients of the catalog, a procedure very necessary to the success of this system,, However with a catalog running to several hundred pages, as many do, the demand for practical loose leaf system increases and without a doubt, if the manufacturing question can be taken care of, will become very popular. Without going into further discussion of the psychology of loose leaf catalog systems, a review of what has already been accomplished, is encouraging.

The success of failure seems to depend entirely upon a binding that can be quickly and easily operated and is not too expensive.

The illustration shows three of the most popular forms; two of them have flexible covers.

“A” has a cloth covering with stubs through which the insidp sheets are held in position, by brass pins or washers. This makes a very good style of binding ior loose leaf work, but of course, the capacity is rather limited*

“B” is another idea of a loose leaf catalog made out of one sheet of paper. This is the cheapest loose leaf binding of which we have knowledge and is fairly satisfactory although will not retain as nice an appearance as cloth bound, owing to the fact that it is not as well made and not as expensive. This is what we might term a Bellos Back cover. Both A and B are fastened with the same kind of brass pins and washers, “A” showing the button side and “B” showing the washer side. The cloth bound Exhibit “B” is adapted for use only on large catalogs. The sample shown has an expansion of eighty per cent, and the covers are fastened together by two screws that fasten into two tubes over which the punch catalog pages are placed. These come in many combinations of leather and cloth and canvas bindings and at a great many prices and can be secured from manufacturing companies making a specialty of this sort of catalog binding. Various manufacturers have different catalog covers operating on this same principle from a single screw post to a triple screw post, depending upon the strength desired. The construction of all catalog covers where an expanding back is wanted, is almost alike. As a rule these bindings have to be made to order as the requirements and sizes are so varied. There is another loose leaf cover made which is the cheapest of the board covered catalogs and can be used when a general utility cover at a low price is desired. It consists of a pair of covers bound in cloth, leather or art canvas, held together by two screw posts and without any back.

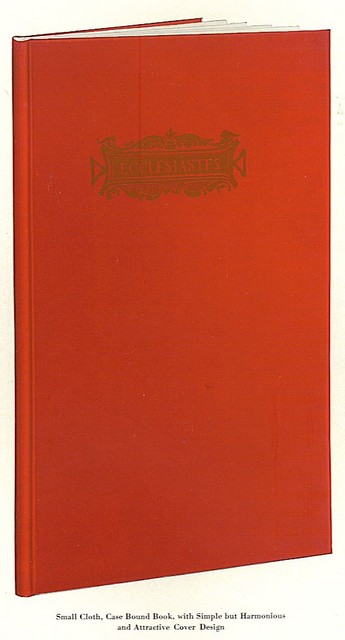

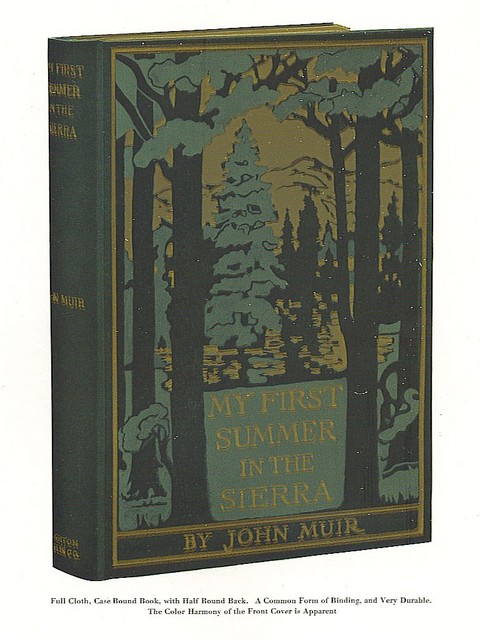

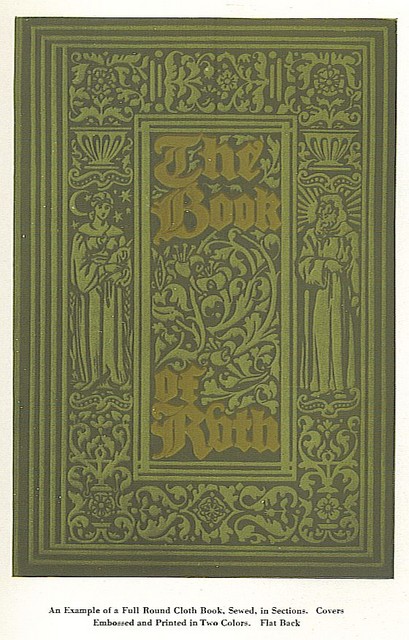

Cased books present a wide range of possibilities, and where such bindings are used on a popular novel, often become extremely beautiful. The designs should always have the commercial viewpoint of attracting the ‘notice of the casual observer, and by means of the cover interesting the observer in the inside pages.

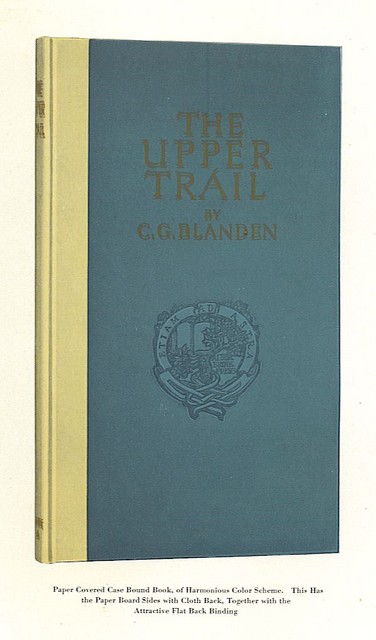

Flat backed books seem to be the most attractive, although the half round back is undoubtedly a better piece of binding. In coverings, the boards, and various canvases on the market, are not the only available materials; oddities, such as Japanese grass cloth, burlap, and even wall papers have been used. Cloth backs and paper board sides or full paper board cases are often used, bearing on their front cover, designs stamped in gold leaf, German color foil, inks, and blind stamping. Examples of elaborate designs on cloth and also paper board sides with cloth backs are here shown. A very simple one with only the title printed on the front cover presents an extremely charming appearance, because the stock used was a rare and lovely piece of paper equal to vellum in quality. Many commercial publishing houses blind stamp their front covers and paste in the space a three-color halftone reproduction. This introduces an element on the cover not otherwise possible of attainment, for three-color half-tone work is not practical on a book cover unless coated paper is used in the binding, and coated papers are not only too brittle, but also soil too readily to serve as a practical covering for books.

An English method of binding which is both dignified and attractive, is to use a plain paper board case with the title printed on a label and pasted both on the front cover and on the back. This is also used on the temporary bindings usually put on finely printed books, the binding being intended merely to serve as protection for the sheets until the purchaser can afford to have the book beautifully bound. These wire sewed sheets bound in a temporary binding have proved not very desirable to the hustling citizen of the United States, who seldom cares either to spend more money or to take the time requisite to a careful rebinding. This has caused publishers to demand and get our standard bindp ing for books and they are usually bound well enough to answer the requirements needed of them in this country. Neverthef-less the demand for extravagant designs and the multitude of good and bad books which one sees at the booksellers, induces a certain regret that in the cased books used or published, we could not have more restraint and even revert to the simple English way of binding.

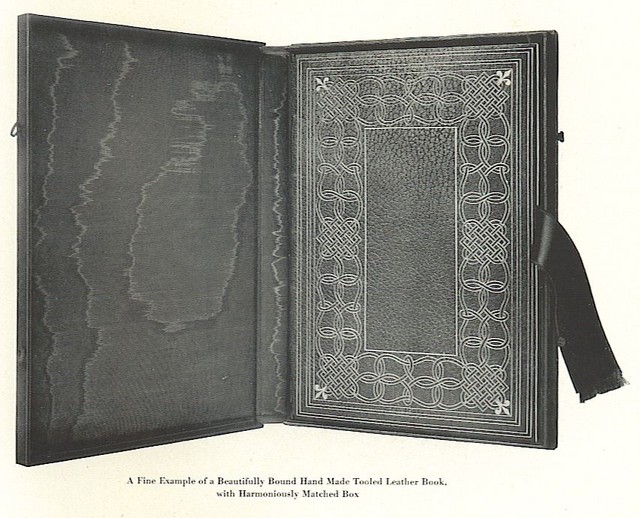

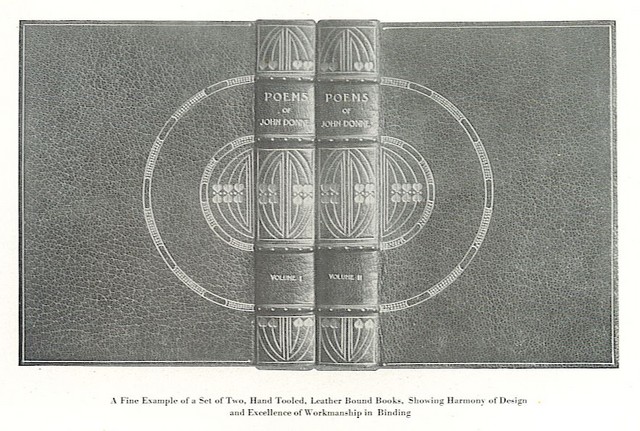

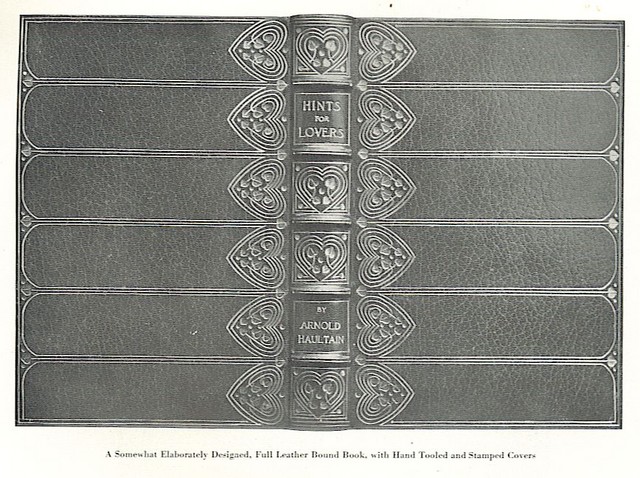

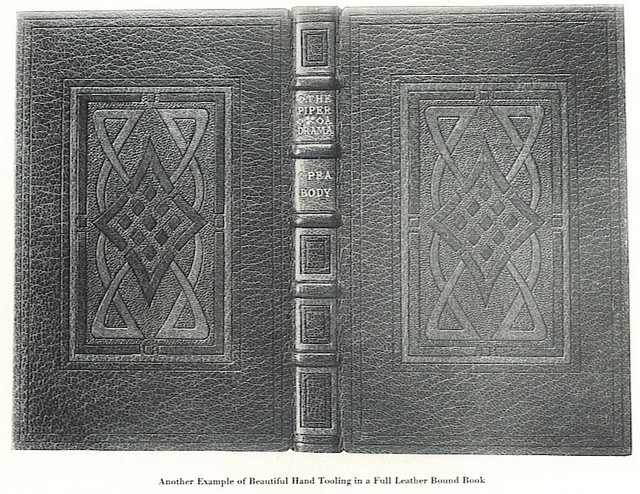

Beyond cased books in quality are the hand-sewed library books and the beautifully bound hand-made books. Each year binders progress in this field of finely sewed and beautifully bound books and it is not hard at present to find binders where work comparable to that done in England and France is produced. Such books may have paper or cloth sides with leather corners and backs (Roxburg) or cloth sides with leather or vellum backs, or may be done in any one of the great number of leathers. France is continually furnishing to our markets newly finished and attractive colors in morocco, calf and pigskins. The colors are as nearly permanent as they ever have been and books bound in these materials are beautiful enough to grace any library. Pigskin is the strongest of these leathers and as it can now be procured in various colors, should be more generally used in the binding of large books.

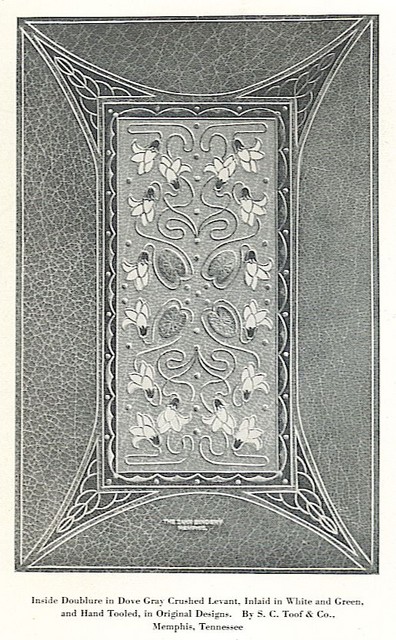

In Italy and Germany a great deal of vellum is used in the binding of library editions and St. Mark’s library in Venice, as well as libraries in most all of the cities in Europe, contains long rolls of old books bound 200 years ago or recently rebound in this very durable and beautiful ivory colored material. While steam heated apartments in our cities cause vellum to warp and twist, it does not do this so freely when it is mounted on paper and it should be used here much more generally than it is as a medium of binding. Of course the main object in the selection of fine material in the binding of individual books, is to give the binder an opportunity which he does not have when cloth or paper are used for the execution of the highest type of design and for the attainment of the greatest beauty in bookbinding. Therefore the test is much more severe when one considers the output from these sources, and it is with pride that we refer to several of the examples here reproduced of bindings made at one or two of our best hand binders. Among the resources used in such work, the inlaying of one leather into the other, the beveling of the corners, the tooling of the inside covers or the addition of elaborate Doub-lais and silk and leather end papers, become quite a feature.

As a whole, the year has been marked particularly by some advance in catalog and booklet work, by an increasing demand for loose leaf binders, which will give the large manufacturer an opportunity of adding the necessary insert pages to his voluminous catalog without being under the necessity of sending an entirely new catalog. The year has witnessed the pushing ahead almost beyond the possibilities of the color and attractiveness obtained in the stamping and binding of cased books. The finest work still comes from the East, where they are given more opportunity to do their best, although the central cities have the ability to produce work comparable to the best, when the occasion presents itself. No manufacturer can produce work consistently, if it is very far above the average required of him by his customer, and until a more comprehensive understanding of the possibilities for beauty as well as effectiveness in booklets and catalogs and all trade publications is acquired by the man who pays for them, it would be unwarranted to expect such results as are usual today in France and Germany. Our output is distinguished by a vigorous and very limited expression of ideas related only to the evident effect intended, in the designs we use on our books; instead of a more restrained, refined, and abstract type of design which is there used, and in- a rougher but more durable type of binding, both in booklets and sewed books.

The exhibits of the various styles of binding found in this section were selected by Ralph Fletcher Seymour, Chicago, from various sources to show the different methods employed by leading binders, and to show some samples of the beautiful effects which are being obtained in this art.

EXHIBITS OF BINDING

METHODS EMPLOYED BY LEADING BINDERS

We are especially indebted to S. C. Toof & Co., of Memphis, Tennessee, for the fine exhibits of hand tooled leather bindings.